Table of Contents

Drive sustainability and profitability with advanced plastics manufacturing software. Optimize materials, energy, and machine performance while meeting your green goals.

Sustainability is truly transforming the plastics industry we all rely on. From the packaging that carries our groceries to the car parts we depend on daily, companies are feeling rising pressure from regulators, customers, and investors to do better. They are being pushed to cut waste, lower emissions, and embrace eco-friendly materials. Change in such a big, traditional industry isn’t easy, but thankfully, digital tools are making the journey smoother and more achievable.

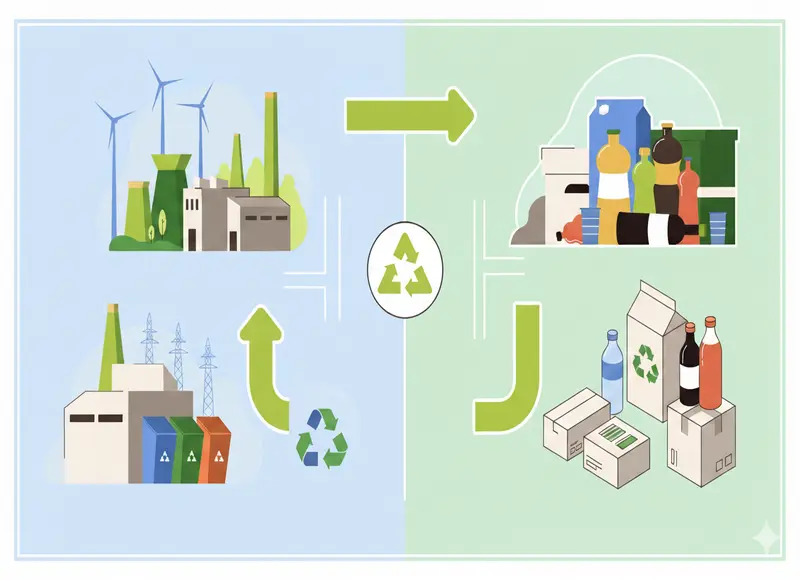

From that visibility, the reductions in waste, the switch to greener inputs, and the fine-tuning of machines to squeeze out maximum output from the same amount of material occur. Eventually, that approach gives rise to a closed-loop system supported by data. It minimizes virgin resin usage and maximizes the recycled content used.

When manufacturing companies integrate real-time data tracking, they see multiple benefits. It helps reduce energy-intensive processes, optimize resources, and maintain quality while meeting environmental targets.

Let us learn more about how this software helps achieve long-term sustainability goals.

Tracking Raw Material Usage

One of the first steps toward sustainability is understanding how materials are being used. For decades, many plants relied on manual logs or spreadsheets to track resin usage, additives, and scrap rates. The problem with those methods is the lack of precision. Small errors in reporting can add up to large blind spots over time.

Modern manufacturing software removes this confusion with automated data collection and material tracking using IoT technology. Sensors on silos, hoppers, and mixers send real-time data to a central system. This helps managers clearly see how materials move through production and spot where waste happens.

The enhanced clarity also facilitates the spotting of different ways to eliminate the unnecessary, replace the inputs with the ones of lower impact, or adjust the machines in order to obtain a higher yield from the same quantity of material. The gradual application of this data-based method to material control eventually results in less dependence on virgin resin and more use of recycled content.

Supporting Recycled and Bio-Based Materials

Switching from virgin plastics to recycled or bio-based alternatives is one of the most visible ways the industry can demonstrate commitment to sustainability. Yet these materials often behave differently during production. Without careful oversight, they can lead to higher defect rates, more downtime, or wasted batches.

This software application helps in bridging the gap in the collection of process and quality data on new materials. For example, with the usage of recycled content, the system records settings for machines, temperature fluctuations, the rate of defects, and energy consumption in real time.

Advanced analytics and machine learning models can then identify correlations between parameters and output quality, helping engineers fine-tune production conditions. Over time, this creates a continuously improving feedback loop in which data, rather than trial and error, guides decision-making. This approach supports the transition toward more sustainable inputs while maintaining product consistency.

Reducing Scrap and Rework

Scrap is not only expensive but also one of the most invisible sources of waste in plastics production. Traditional processes often produce more rejects than necessary simply because operators lack timely feedback.

Plastics manufacturing software integrates real-time quality control with production execution. Machine vision systems and in-line sensors detect defects instantly, while predictive alerts notify operators when a process drifts out of specification. These capabilities allow proactive interventions before scrap accumulates.

Moreover, integrated analytics dashboards are employed to identify recurring defect patterns to perform root-cause analysis for process optimization. Cost of non-conformance and material wastage are reduced because of early catch of issues and running fewer unplanned rework processes; hence, production efficiency is linked with sustainability goals.

Measuring Energy Consumption

Materials are not the only sustainability concern. Energy use is another critical area, as plastics production is often energy-intensive. Managers who want to cut carbon footprints need accurate data to identify where improvements are possible.

Manufacturing software provides this visibility by tracking energy consumption at the machine, line, and plant levels. Smart meters and connected controllers record data automatically and feed it into energy management dashboards.

Reports might improve understanding of energy-hungry processes and whether scheduling, maintenance, or machine calibration can bring down maximum energy usage. Some tools harness AI energy optimization to automatically adjust machine loads and reduce peak demand. Increases in energy efficiency by even a minor fraction are of value to sustainability parameters and general profitability.

Streamlining Compliance and Reporting

Sustainability is not just about internal goals; it is also about proving progress to regulators, partners, and customers. Generating reports on recycled content, waste reduction, or emissions can be daunting without a reliable system for gathering and verifying data.

Manufacturing software eases the life of an operator by automating data logging, audit trails, and digital reporting tools. The systems of production, procurement, and/or quality control may be combined into one sustainability dashboard. Documentation may then be given accurately and timely at a moment's notice to auditors and customers.

This not only reduces the administrative burden but also ensures traceability and compliance with evolving regulations such as the EU Green Deal, Extended Producer Responsibility (EPR) rules, or ISO 14001 environmental standards.

Encouraging Continuous Improvements

Sustainability is not a one-time activity. It may need continual changes with the emergence of new materials, changes in laws, and alterations in consumer behavior expectations. Companies treating it as an attainable end goal will fall behind.

Software encourages continuous improvement by making performance metrics visible, comparable, and actionable over time. Through data visualization, KPIs, and trend analytics, plants can benchmark sustainability performance across sites, set new targets, and measure progress month over month.

Collaborative system platforms are increasingly recognizing that one plant should share best practices for replication and execution across the enterprise. The continual feedback loop stops momentum from dying and is designed, instead, for a translation of sustainability into everyday decision-making, rather than its being a one-off initiative.

Fostering Innovation in Materials

Perhaps one of the most exciting impacts of software is how it supports experimentation with new materials. Bio-plastics, composites, and advanced polymers often require unique production conditions. Without detailed data, experimenting with them can feel risky and expensive.

The trial-run information is used to make the development of control software a rather data-rich process. Engineers can evaluate manufacturing situations via a digital twin, verify parameters virtually, and then finally validate them on the shop floor with the least quantity of waste.

As data accumulates, predictive analytics can forecast material behavior under varying conditions. This accelerates research and development while enabling faster scale-up. The ability to innovate with confidence is essential for moving the plastics industry toward more sustainable materials and production methods.

Final Thoughts

The plastics industry encounters serious challenges with respect to adapting to the world's sustainability drive. Change, therefore, is not optional; if a company ignores it, it shall soon find itself losing customers as well as regulatory approval.

Alongside a few good digital tools combining automation, IoT connectivity, and analytics, the transition need not interfere with operations or increase cost.

Plastics manufacturing software is, in a way, the bridge between efficient production and green practice, an endeavor that looks to design a future where production meets sustainability all altogether.

Recent Blogs

The Role of Artificial Intelligence in Modern Law Firm Growth Strategies

-

03 Mar 2026

-

6 Min

-

104

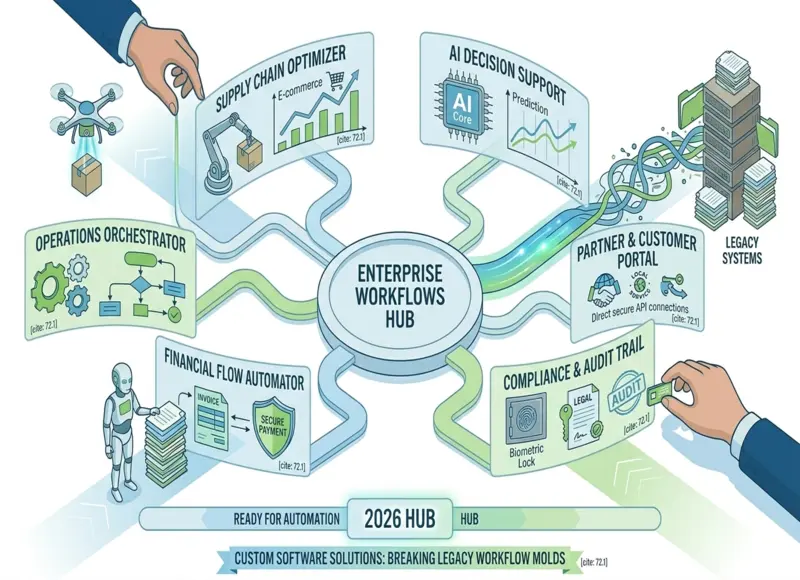

How Custom Software Companies Help Enterprises Automate Complex Workflows

-

03 Mar 2026

-

5 Min

-

127